Medicine has revolutionized with the integration of 3D printing technology into healthcare practices. Imagine a world where complex surgical procedures are meticulously planned with personalized 3D-printed models of organs, allowing for precise and tailored interventions. With advancements in bioprinting, you can explore how 3D printers are creating living tissues and organs for transplantation, offering hope to patients in need of organ replacements. From prosthetics to dental implants, the possibilities in healthcare are endless with 3D printing technology at the forefront of innovation.

Key Takeaways:

- Precision: 3D printing allows for the creation of highly customized and precise medical implants and devices tailored to individual patients.

- Cost-Effective: By streamlining the manufacturing process, 3D printing in healthcare can reduce costs associated with traditional methods of production, such as molding or machining.

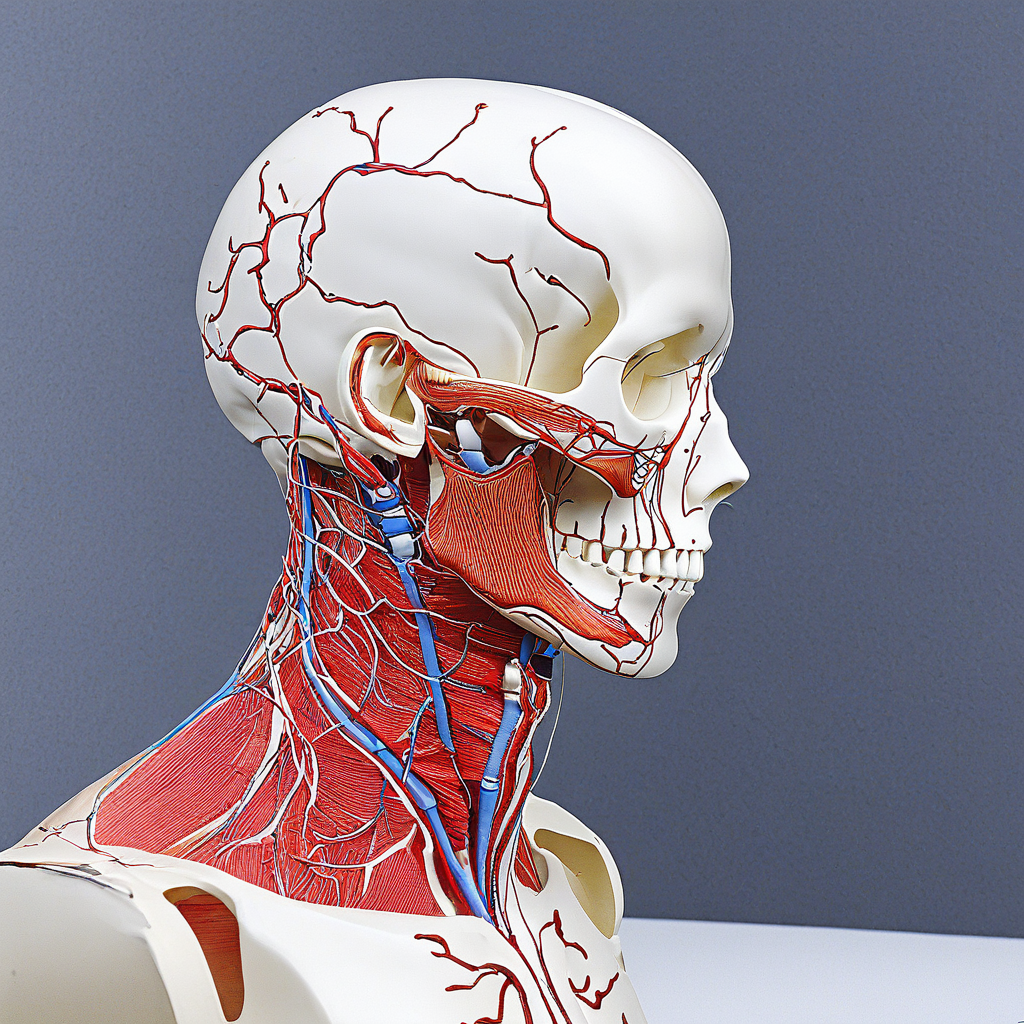

- Medical Education and Training: 3D printing is used to produce anatomical models for medical education and surgical training, allowing healthcare professionals to practice complex procedures in a realistic and safe environment.

Revolutionizing Prosthetics and Implants

Customized prosthetic limbs

For amputees, 3D printing technology has opened up a world of possibilities by enabling the creation of customized prosthetic limbs. Traditional prosthetics can be uncomfortable and ill-fitting, leading to mobility issues and discomfort. However, with the advent of 3D printing in healthcare, prosthetic limbs can now be tailored to fit the individual’s anatomy perfectly, providing a more comfortable and functional solution.

Personalized implants for better fit and functionality

With 3D printing, personalized implants can be created to precisely fit a patient’s unique anatomy, resulting in better functionality and improved outcomes. Whether it’s a hip implant, dental implant, or even a cranial implant, the ability to customize the implant ensures a more natural fit and reduces the risk of complications. This level of personalization is revolutionizing the field of implantology, offering patients a tailor-made solution that meets their specific needs and enhances their quality of life.

Personalized implants not only improve the fit and functionality but also contribute to faster recovery times and reduced risk of post-operative complications. By precisely matching the patient’s anatomy, 3D-printed implants provide a more seamless integration with the surrounding tissues and bones, promoting better healing and long-term success of the implant.

Enhancing Surgical Planning and Training

Accurate anatomical models for surgical rehearsal

Planning a surgical procedure can be challenging, but with 3D printing technology, surgeons can now have access to accurate anatomical models that replicate a patient’s specific anatomy. These models allow you to visualize the intricate structures of the body, helping you plan and rehearse the surgery before stepping into the operating room. By holding a tangible model in your hands, you can better understand the complexities of the case and develop a more precise surgical plan.

Virtual reality training for surgeons

Enhancing surgical training, virtual reality technology combined with 3D printing is revolutionizing how surgeons prepare for complex procedures. By immersing yourself in a virtual environment, you can practice surgeries in a risk-free setting, sharpening your skills and gaining confidence before performing the procedure on a real patient. This innovative training method allows you to make mistakes, learn from them, and improve your surgical techniques without putting any patient at risk.

The use of virtual reality in surgical training not only benefits aspiring surgeons but also provides experienced practitioners with opportunities to enhance their skills. By simulating a variety of scenarios and complications, virtual reality training ensures that you are well-prepared to handle any situation that may arise during surgery.

Creating Personalized Medication and Dosage

Allowing for personalized medication and dosage is one of the significant contributions of 3D printing in healthcare. Through this innovative technology, medications can be tailored to individual needs, ensuring optimal treatment outcomes.

3D-printed pills with customized release rates

Dosage customization is crucial for many patients, especially those with specific requirements for the release rate of medications. With 3D printing, pills can be designed with intricate structures that control how the medication is released in the body. This technology enables healthcare providers to create pills with customized release rates, improving efficacy and reducing side effects for patients.

Tailored dosage forms for individual patients

To provide tailored dosage forms for individual patients, 3D printing allows for the creation of medications in specific shapes, sizes, and formulations. This personalization ensures that patients receive the exact dosage they need, especially beneficial for children, elderly individuals, or those with swallowing difficulties. By adjusting the dosage form to suit the patient’s requirements, healthcare providers can enhance medication adherence and overall treatment effectiveness.

The ability to tailor dosage forms for individual patients using 3D printing marks a significant advancement in healthcare. By customizing medications to meet specific patient needs, healthcare providers can improve treatment outcomes and quality of care.

Improving Tissue Engineering and Regeneration

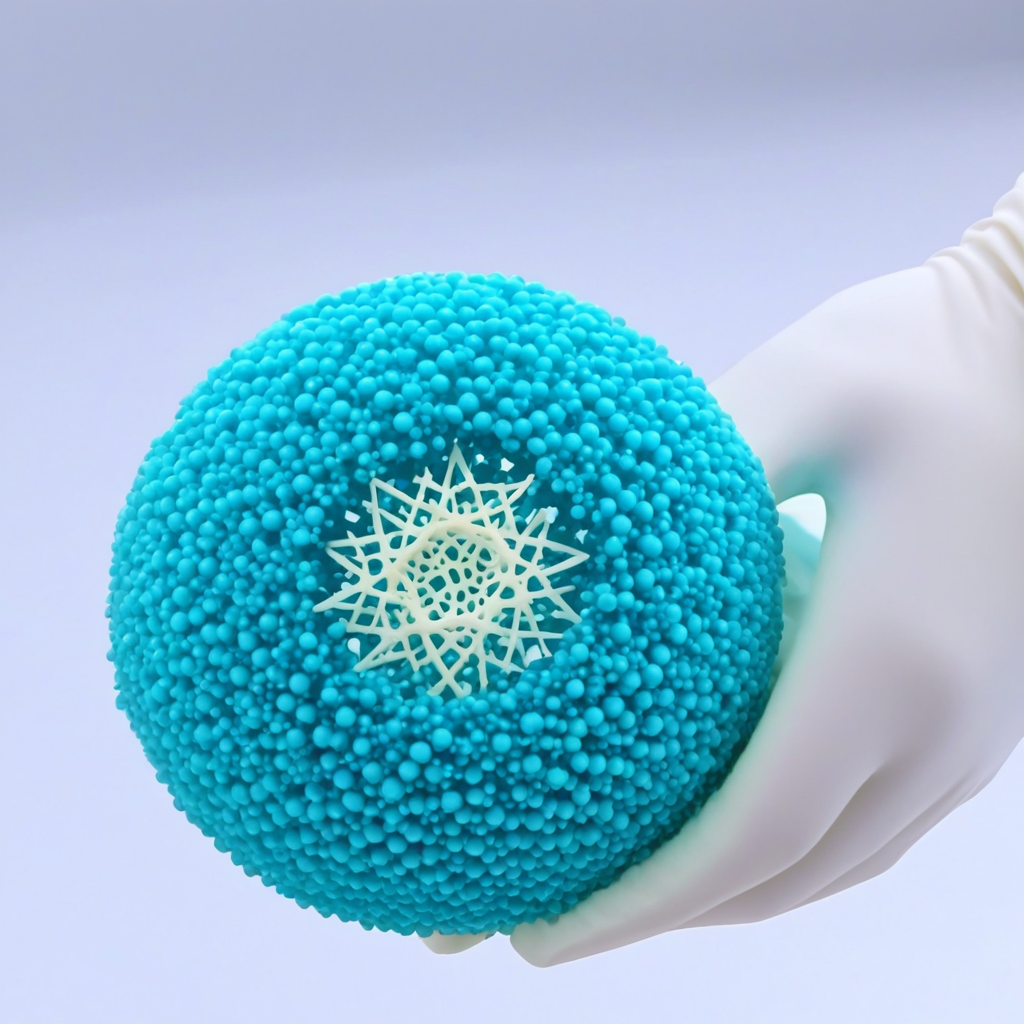

Bioprinting functional tissue structures

Engineering functional tissue structures using 3D bioprinting has revolutionized the field of tissue engineering. By precisely depositing layers of biomaterials, cells, and growth factors, researchers can recreate complex tissue architectures that mimic the native structure of organs like skin, cartilage, and even blood vessels. This technology offers the potential to customize implants that are biologically functional, reducing the risk of rejection and improving patient outcomes.

Developing biomaterials for tissue repair

Any advancement in tissue engineering heavily relies on the development of suitable biomaterials that can support cell growth and tissue regeneration. Researchers are actively exploring various biocompatible materials, such as hydrogels and bioinks, that can mimic the native extracellular matrix of different tissues. By fine-tuning the properties of these biomaterials, they can create a conducive microenvironment for cells to proliferate and differentiate into specific tissue types.

For instance, hydrogels with tunable mechanical properties can provide structural support during the initial stages of tissue formation and gradually degrade as new tissue is generated. This temporal control over the biomaterial properties is crucial for ensuring successful tissue regeneration without causing inflammatory responses or adverse reactions in the body.

Streamlining Medical Device Manufacturing

Rapid prototyping and production of medical devices

Not only does 3D printing allow for the rapid prototyping of medical devices, but it also streamlines the production process. With this technology, you can quickly design and manufacture complex medical devices with intricate details that may be challenging or impossible with traditional manufacturing methods. This not only reduces the time it takes to bring a new device to market but also allows for quick iterations and improvements based on feedback.

Cost-effective production of customized devices

Medical professionals can now leverage 3D printing to produce customized devices tailored to the specific needs of individual patients. With this capability, you can create personalized prosthetics, implants, or surgical tools that perfectly fit the anatomy of the patient, enhancing treatment outcomes and comfort. Additionally, you can optimize the design of these devices to improve functionality and reduce manufacturing costs, ultimately making healthcare more affordable and accessible.

Furthermore, the ability to produce customized devices on-site can significantly reduce lead times and costs associated with traditional manufacturing processes, such as outsourcing production or waiting for shipments to arrive. This not only improves efficiency in healthcare facilities but also allows for a more agile response to patient needs, ensuring timely delivery of tailored solutions.

Advancing Diagnostic Capabilities

Unlike traditional imaging techniques like MRI or CT scans, 3D printing offers a tangible and accurate way to visualize complex anatomical structures and pathology. This technology allows healthcare professionals to create patient-specific 3D-printed models that can be used for surgical planning, education, and communication with patients and their families.

3D-printed models for disease visualization

On the forefront of diagnostic innovation, 3D-printed models are revolutionizing the way healthcare providers approach disease visualization. These models allow for a deeper understanding of conditions such as tumors, cardiac anomalies, and skeletal deformities by providing a physical representation that can be held, examined, and strategized upon.

Personalized diagnostic tools for rare conditions

3D printed Personalized diagnostic tools go even further by offering customized solutions for rare and complex medical conditions. By utilizing 3D printing technology, healthcare professionals can create intricate models that mimic a patient’s unique anatomy, enabling more precise diagnosis and tailored treatment plans for conditions that may be challenging to address using conventional methods.

Diagnostic Furthermore, these personalized tools can aid in preoperative assessments, allowing surgeons to practice procedures and anticipate potential complications, ultimately improving surgical outcomes and patient care in cases where every detail matters.

Summing up

Ultimately, 3D printing has revolutionized healthcare by providing innovative solutions for personalized medicine, prosthetics, surgical planning, and medical education. Your understanding of how 3D printing is used in healthcare can open your eyes to the incredible possibilities and advancements in the medical field. As technology continues to evolve, the potential for 3D printing to further enhance patient care and treatment options is vast. Embracing this cutting-edge technology can lead to better outcomes, improved patient experiences, and a brighter future for healthcare.

Read our Latest Blogs & Product reviews on 3D Printing

FAQ

Q: How is 3D printing used in healthcare?

A: 3D printing is utilized in healthcare for various applications such as creating customized prosthetics, implants, surgical instruments, anatomical models for pre-surgical planning, and drug delivery systems. It allows for precise and personalized solutions that can improve patient outcomes.

Q: What are the benefits of using 3D printing in healthcare?

A: Some benefits of using 3D printing in healthcare include faster production of customized medical devices, reduced surgery time due to pre-surgical planning with anatomical models, improved patient care with personalized solutions, and lower costs compared to traditional manufacturing methods for certain medical devices.

Q: Are there any limitations or challenges to using 3D printing in healthcare?

A: While 3D printing offers many advantages in healthcare, there are some limitations and challenges to consider. These include regulatory hurdles for medical device approval, ensuring the quality and safety of 3D printed medical products, the need for specialized training for healthcare professionals to utilize 3D printing technology effectively, and the cost of implementing and maintaining 3D printing systems in healthcare settings.