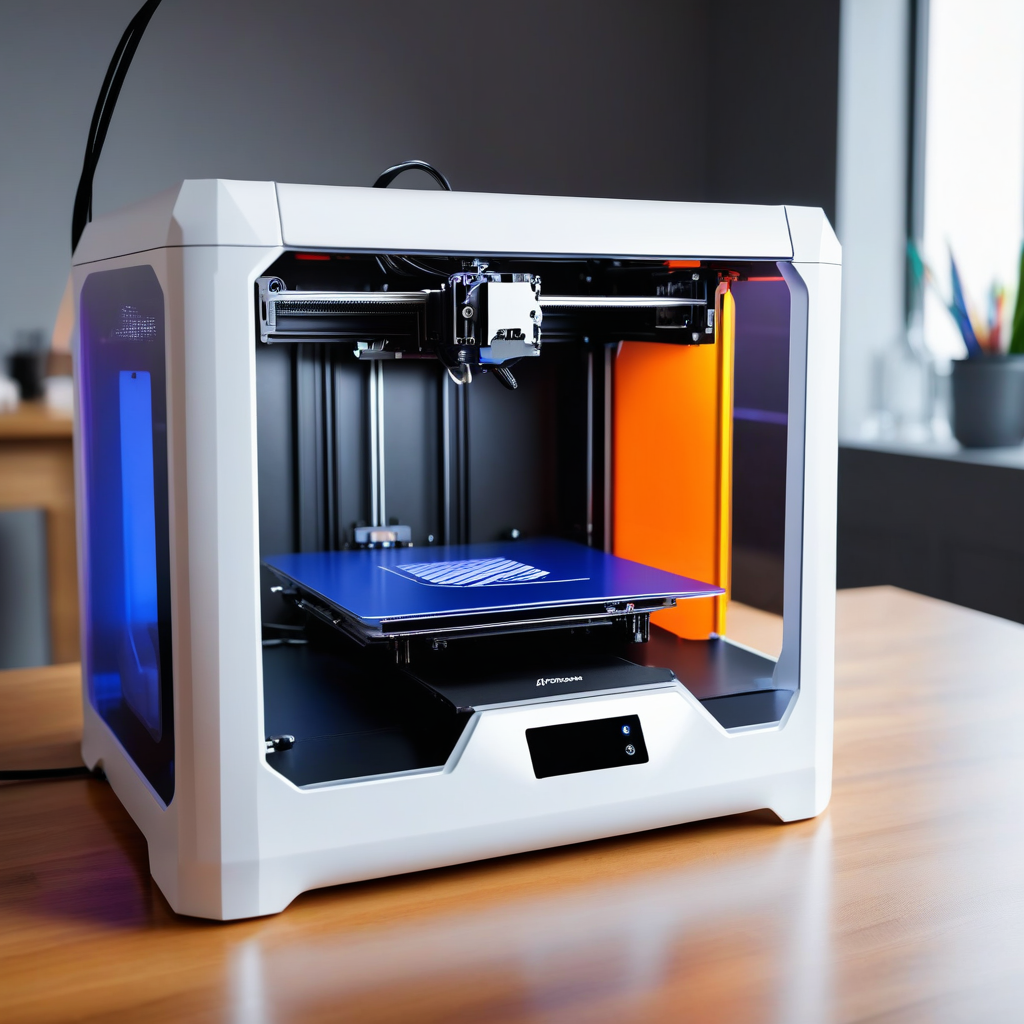

3D Printer technology has come a long way, allowing you to bring the power of creating three-dimensional objects right to your desktop. With a desktop 3D printer, you can turn digital designs into physical objects by layering material to build up the final product. These compact machines offer a fascinating glimpse into the future of manufacturing, empowering you to unleash your creativity and bring your ideas to life right in your own home.

Key Takeaways

- Desktop 3D printers are small and affordable machines that can create three-dimensional objects by laying down layers of materials like plastic or resin.

- They are versatile tools that can be used for rapid prototyping, small-scale production, educational purposes, and even hobbyist projects.

- Desktop 3D printers offer the convenience of being able to print objects in the comfort of your own home or office, without the need to outsource the manufacturing process.

Definition and History

Origins of 3D printing

Before we investigate into understanding what a desktop 3D printer is, let’s explore the origins of 3D printing. The concept of 3D printing dates back to the 1980s when Chuck Hull invented stereolithography, which involved using light to solidify layers of a liquid resin to create 3D objects. This groundbreaking technology laid the foundation for what we now know as 3D printing.

Evolution of desktop 3D printing

History shows that desktop 3D printing has come a long way since its inception. As technology advanced and became more accessible, desktop 3D printers emerged, allowing enthusiasts, hobbyists, and professionals to bring their ideas to life in the comfort of their homes or workshops. These compact machines have revolutionized the way we prototype, design, and manufacture objects, making the process more agile and cost-effective.

A desktop 3D printer is a compact machine that uses additive manufacturing technology to create three-dimensional objects layer by layer from a digital design. These machines have become increasingly popular due to their affordability, ease of use, and versatility. Whether you are a student, artist, engineer, or DIY enthusiast, a desktop 3D printer can be a valuable tool in unleashing your creativity and bringing your ideas into the physical world.

Key Components

Print bed and extruder

For a desktop 3D printer, the print bed is where your object is fabricated layer by layer. It needs to be flat, stable, and properly leveled to ensure the accuracy of your prints. The extruder is responsible for melting the filament and depositing it onto the print bed, following the instructions from the 3D model you’ve designed.

Filament types and materials

Materials for 3D printing come in various types and compositions. Some common filament materials include PLA, ABS, PETG, TPU, and more. Each material has its unique properties, such as strength, flexibility, and heat resistance, making them suitable for different types of projects. After selecting the material, make sure your 3D printer is compatible with it to avoid any issues during printing.

| Materials | Types |

| PLA | Biodegradable, easy to print |

| ABS | Durable, heat-resistant |

| PETG | Strong, impact-resistant |

| TPU | Flexible, elastic |

| Others | Specialized for specific purposes |

Control systems and software

Any desktop 3D printer requires control systems and software to operate. These systems dictate how your printer moves, how the filament is extruded, and other critical functions. The software you use to prepare your 3D models for printing can greatly impact the quality of your final print. Make sure to choose software that is user-friendly and compatible with your printer.

Understanding how these key components work together will help you optimize your desktop 3D printing experience. By familiarizing yourself with the print bed, extruder, filament types, and control systems, you can produce high-quality 3D prints efficiently and effectively.

Types of Desktop 3D Printers

For a comprehensive understanding of desktop 3D printers, it’s crucial to grasp the various types available. Each type operates uniquely, offering distinct advantages and disadvantages. To help you navigate this diverse landscape, here are the primary types of desktop 3D printers in a simplified format:

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) |

| Selective Laser Sintering (SLS) | Binder Jetting |

Fused Deposition Modeling (FDM)

On the FDM printers, thermoplastic filaments are melted and extruded layer by layer to create the final 3D object. This method is widely used due to its affordability and ease of use, making it popular among hobbyists and beginners. Perceiving the simplicity of FDM printers, you can quickly create prototypes or personalized items right from your desktop.

Stereolithography (SLA)

With Stereolithography (SLA) printers, objects are created by curing liquid resin using a UV laser. These printers offer exceptional precision and produce high-quality, smooth surfaces, making them suitable for detailed prototypes and intricate designs. Stereolithography printers provide excellent resolution, allowing you to create intricate models with intricate details.

Selective Laser Sintering (SLS)

To examine deeper into desktop 3D printing, you’ll encounter Selective Laser Sintering (SLS) printers that use a laser to sinter powdered material, typically nylon or metal, layer by layer. For instance, SLS printers offer the flexibility to produce functional prototypes and end-use parts with robust mechanical properties and intricate designs.

Binder Jetting

For a unique desktop 3D printing experience, Binder Jetting printers deposit a binding agent onto a powdered material, layer by layer, to create the desired object. This method is renowned for its speed, cost-effectiveness, and ability to produce large parts. Stereolithography printers provide excellent resolution, allowing you to create intricate models with fine details.

How Desktop 3D Printers Work

Layer-by-layer printing process

With desktop 3D printers, the magic happens through a layer-by-layer printing process. This process involves melting material, typically plastic filament, and extruding it through a nozzle onto a build platform. The printer lays down each layer of material according to the design blueprint provided by the 3D model. As each layer is added, the object takes shape, gradually building upwards until the entire object is complete.

Printing speed and resolution

Layer-by-layer printing allows for precise control over the details of the object being printed. The speed at which a desktop 3D printer can produce an object depends on factors such as layer height and print head speed. Higher resolutions require thinner layers, which can increase printing time but result in finer details and smoother surfaces.

Another crucial factor in 3D printing is the resolution, which determines the level of detail and quality of the finished object. Resolution is measured in microns, with smaller values indicating higher resolutions. Desktop 3D printers can achieve resolutions ranging from 20 to 200 microns, with higher-end printers offering even greater precision.

Post-printing processing and finishing

Desktop 3D printers can produce amazing objects, but the process doesn’t end once the printing is done. Post-printing processing and finishing are crucial steps to ensure the final product meets your expectations. This may involve removing support structures, sanding rough edges, and applying finishes like paint or varnish to enhance the appearance of the object.

Processing and finishing your 3D prints can take some time and effort, but the results are well worth it. Taking care to properly finish your prints will not only improve their aesthetic appeal but also ensure that they are structurally sound and durable. With a little attention to detail, you can turn your 3D prints into professional-quality objects that you’ll be proud to display.

Applications and Uses

Rapid prototyping and product design

Now, let’s explore some of the key applications of desktop 3D printers. One of the primary uses of these printers is in rapid prototyping and product design. With a desktop 3D printer, you can quickly and cost-effectively create physical prototypes of your designs. This allows you to test different iterations, make adjustments, and refine your product design before moving on to full-scale production.

Hobbyist and DIY projects

An exciting application of desktop 3D printers is in hobbyist and DIY projects. Whether you enjoy model-making, crafting, or tinkering with electronics, a 3D printer can bring your projects to the next level. You can create custom parts, intricate designs, and functional prototypes right from the comfort of your own home.

Rapid prototyping opens up a world of possibilities for creating unique and personalized items, from intricate jewelry to custom home decor. The only limit is your imagination!

Educational and research purposes

Purposes educational institutions and research facilities also benefit greatly from desktop 3D printers. These printers offer a hands-on way for students and researchers to learn about design principles, engineering concepts, and manufacturing processes. By actually creating physical objects, students can better understand theoretical concepts and gain practical skills that are valuable in today’s workforce.

Plus, research labs can utilize desktop 3D printers to prototype new inventions, develop custom equipment, and conduct experiments more efficiently. The speed and versatility of 3D printing make it a valuable tool in the educational and research fields.

Small-scale manufacturing and production

Educational projects as entrepreneurs and small businesses are increasingly turning to desktop 3D printers for small-scale manufacturing and production. These printers allow you to produce limited runs of custom products, create prototypes for investor pitches, or even start a small production line for niche items. With a desktop 3D printer, you can quickly iterate on designs, produce small batches of products, and bring your ideas to market faster and more affordably than traditional manufacturing methods.

Benefits and Limitations

Advantages of desktop 3D printing

To fully grasp the benefits of desktop 3D printing, you must understand its transformative power. This technology allows you to bring your ideas to life right in front of your eyes. With a desktop 3D printer, you have the ability to create custom objects quickly and easily, from prototypes to personalized gifts. The creative freedom it offers is unparalleled, enabling you to explore your imagination and turn concepts into tangible objects without the need for expensive manufacturing processes.

Challenges and limitations of desktop 3D printing

Advances in desktop 3D printing are remarkable, providing accessibility and affordability to a once exclusive realm. However, limitations still exist that you should be aware of. One challenge is the size constraints of desktop 3D printers, restricting the dimensions of objects you can produce. Additionally, the quality of prints may not always meet industrial standards, requiring post-processing to refine the final product. You may also encounter issues with material choices, as not all materials are compatible with desktop 3D printers, limiting the variety of objects you can create.

Understanding these limitations will help you manage your expectations and utilize desktop 3D printing technology to its fullest potential. By acknowledging the constraints, you can plan your projects accordingly and leverage the advantages of this innovative tool effectively.

Final Words

Taking this into account, you now have a better understanding of what a desktop 3D printer is and how it works. These innovative machines allow you to bring your ideas to life in a tangible form, making rapid prototyping and customization more accessible than ever before. With a desktop 3D printer, you have the power to create personalized items, prototype inventions, and explore your creativity in ways that were once out of reach.

FAQ

Q: What is a desktop 3D printer?

A: A desktop 3D printer is a type of 3D printer that is designed for use in a small office or home environment. These printers are compact in size and are typically more affordable than industrial-grade 3D printers. They work by using layered additive manufacturing technology to create three-dimensional objects from a digital file.

Q: How does a desktop 3D printer work?

A: Desktop 3D printers work by melting material, often plastic filament, and depositing it layer by layer to create a three-dimensional object. The printer reads a digital file, usually in the form of a 3D model, and follows the instructions in the file to build the object. Depending on the printer and the material used, the printing process can take several hours to complete.

Q: What can you make with a desktop 3D printer?

A: A desktop 3D printer can be used to create a wide range of objects, including prototypes, toys, household items, jewelry, and even replacement parts. The versatility of desktop 3D printers makes them popular among hobbyists, designers, engineers, and educators who want to bring their ideas to life in a physical form.