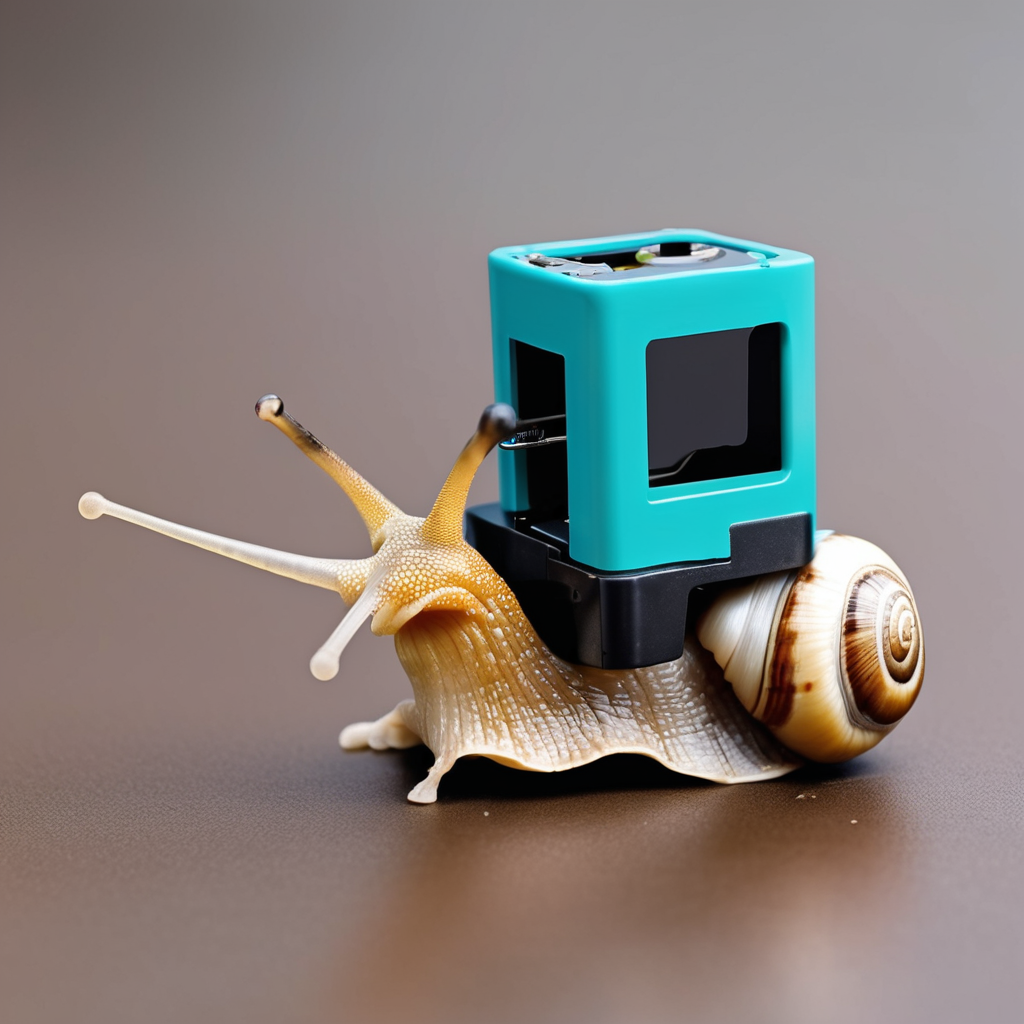

With its precision and intricate capabilities, 3D printing is often seen as a slow process. In this exploratory article, we explore into the reasons behind this perception. From the additive nature of 3D printing technology to the intricate details that require careful precision, we unravel the complexities that contribute to the extended duration of 3D printing processes. Stay tuned to uncover the secrets behind the speed of 3D printing and how you can optimize your printing experience.

Key Takeaways

- 3D Printing Process Duration: The time it takes for a 3D printing process can vary depending on factors like size, complexity, and technology employed, ranging from minutes to multiple days.

- Factors Contributing to Slow Printing: The additive nature of 3D printing, precision and accuracy requirements, and complexity of the printed object all contribute to the extended duration of the process.

- Improving Printing Speed: Adjusting print settings, such as increasing print speed and reducing layer height, can help make your 3D printer faster. Experimenting with these settings can lead to quicker printing results without sacrificing quality.

How Long Does a 3D Printing Process Usually Take?

Factors Affecting Print Time

- Size of the object being printed

- Complexity of the design

- Type of printing technology used

Knowing these factors can help you estimate the time needed for your 3D printing process.

Print Time Ranges

Printing times for 3D objects can vary significantly, ranging from as short as 30 minutes to multiple days. Smaller and simpler objects might take only a few hours, whereas larger or more intricate items could require several days or even weeks. The complexity and design intricacy play a crucial role in determining the duration of the 3D printing process.

Factors such as the size, complexity, and printing technology employed directly influence how long a 3D printing process will take. Understanding these factors can help you manage your expectations and plan accordingly for your printing projects.

Why is 3D Printing So Slow?

3D Printing Technology

Printing using 3D technology builds objects layer by layer, from the bottom up. This precise method allows for intricate details but requires time as each layer must be laid down and adhered to the previous layer.

Additive Process vs. Subtractive Manufacturing

On the one hand, additive manufacturing, like 3D printing, adds material to create objects layer by layer. On the other hand, subtractive manufacturing removes material to achieve the desired shape.

For instance, while 3D printing adds material where needed, traditional subtractive processes like CNC machining carve out excess material from a solid block.

Layer Thickness and Print Time

Process-wise, the layer thickness in 3D printing directly influences print time. Thinner layers add more intricacy to the design but also increase the overall time required for printing.

Printing very thin layers, often just fractions of a millimeter thick, contributes to the detailed precision of 3D objects but extends the total printing time depending on the complexity of the design.

Precision and Accuracy in 3D Printing

Importance of Precise Movement

Precise movement in 3D printing is crucial for ensuring the accuracy and quality of the final product. The printer’s extruder or laser must move with great precision along the designated path to deposit the material accurately. This meticulous process, while time-consuming, is important for creating intricate and detailed objects.

Accurate Material Deposition

For a 3D print to be successful, the material must be accurately deposited layer by layer. Each layer needs to adhere properly to the previous one to ensure structural integrity. This process of precise material deposition is a key factor in achieving high-quality 3D prints.

The accurate deposition of material in 3D printing is crucial for creating objects with intricate details and complex geometries. Each layer must be carefully laid down to ensure the final product is flawless. This careful process, although time-consuming, is necessary for producing high-quality prints that meet the desired specifications.

Curing and Solidification Time

Accuracy in curing and solidification time is another important aspect of 3D printing. Depending on the type of printing technology used, each layer may require time to cure or solidify before the next layer can be applied. This additional step adds to the overall printing time but is vital for ensuring the structural integrity and quality of the final object.

Another crucial factor in 3D printing is the curing and solidification time of each layer. The material must have sufficient time to solidify before the next layer is added to maintain the structural integrity of the object. This process, although time-consuming, is necessary for creating durable and high-quality 3D prints.

Complexity of the 3D Printed Object

Simple vs. Complex Geometries

To understand why 3D printing can be slow, we must consider the complexity of the object being printed. Simple geometries, such as basic shapes, can be printed relatively quickly. However, more intricate designs with overhangs, undercuts, or internal cavities require more time to print.

Additional Support Structures

Complex geometries often require the use of additional support structures during the printing process. These supports increase the total amount of material printed and extend the printing time. After printing, these supports need to be carefully removed and cleaned up, further adding to the post-processing time.

The complexity of the design directly affects the time needed for 3D printing. Models with more intricate details or unconventional shapes may require additional supports to ensure structural integrity during the printing process. These supports add time to the overall printing and post-processing stages, but they are imperative for achieving the desired final result.

Post-Processing Time

Additional steps in the post-processing phase, such as removing support structures and fine-tuning the object, contribute to the overall time taken by the 3D printing process. Post-processing time can vary depending on the complexity of the design and the level of detail required in the final printed object.

Post-processing time is necessary to ensure the printed object meets the desired quality standards. This stage involves carefully removing any support structures, smoothing out rough edges, and any other finishing touches required to achieve a polished final product. While it adds time to the overall process, post-processing is crucial for producing high-quality 3D prints.

Material and Printer Type

Influence on Print Speed

All 3D printing materials have their own unique properties that can affect the printing speed. Some materials may require longer cooling times between layers, while others may have specific printing requirements that slow down the process. Additionally, the type of 3D printer being used, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), or Selective Laser Sintering (SLS), can also impact the speed of printing.

Choosing the Right Printer

When choosing a 3D printer, consider the specific requirements of your project. If speed is a priority, look for a printer that is known for its fast printing capabilities without compromising quality. Printers with larger build volumes can also accommodate bigger projects, reducing the need for splitting the design into smaller parts and assembling them later.

Optimizing Print Settings

Increasing Print Speed

Optimizing print settings can significantly improve the speed of your 3D printer. By increasing the print speed, reducing the layer height, and choosing a lower infill density, you can expedite the printing process without compromising the quality of your prints.

Reducing Layer Height

Print settings such as reducing the layer height can also impact the speed of your 3D printer. With a lower layer height, the printer will need to deposit more layers to complete the object, potentially increasing printing time. However, this can result in finer details and smoother surfaces on your prints.

Lower Infill Density

For faster printing, consider lowering the infill density setting. Infill density refers to the amount of material inside the 3D printed object. By reducing the infill density, less material is used, leading to quicker print times. This can be particularly useful for objects where structural integrity is not a major concern.

Frequently Asked Questions about “Why is 3D Printing So Slow”

How Can I Make My 3D Printer Faster?

With 3D printing, increasing the print speed, reducing the layer height, and choosing a lower infill density can help speed up the process. Experimenting with these settings can lead to faster and more efficient 3D printing results.

What Happens If You 3D Print Too Slow?

The speed of 3D printing plays a crucial role in the quality of the final product. Printing too slowly can result in issues such as filament oozing, leading to stringing or blobs on the print. It can also increase the risk of warping as the layers cool unevenly.

Is It Normal for 3D Prints to Take Days?

For 3D printing, it is indeed normal for prints to take days, depending on the size and complexity of the object. Print times can vary from a few hours to several days, with more intricate or larger designs requiring extended durations for completion.

Conclusion

With these considerations in mind, the slow nature of 3D printing can be better understood. It is a meticulous process that relies on intricate detailing and layer-by-layer construction. Factors such as technology, precision, and complexity all contribute to the time-consuming aspect of 3D printing. By selecting the right settings and printers tailored to specific needs, users can enhance their 3D printing experience without sacrificing quality. While patience is required, the results are often worth the wait, producing intricate and detailed objects that traditional manufacturing methods struggle to replicate.

FAQ

Q: Why is 3D printing often perceived as a slow process?

A: 3D printing is often seen as slow due to its additive nature. Unlike traditional manufacturing methods that remove material to create an object, 3D printing builds objects layer by layer from the bottom up, requiring each layer to be laid down and properly adhered to the previous layer, hence taking more time.

Q: How long does a 3D printing process usually take?

A: The duration of a 3D printing process can vary based on factors like size, complexity, and technology used. Print times range from 30 minutes to multiple days. Smaller and simpler objects may take only a few hours, while larger or more intricate items could require several days or weeks to complete.

Q: What factors contribute to the slow pace of 3D printing?

A: The extended duration of 3D printing processes can be attributed to factors such as the specific 3D printing technology employed, the precision and accuracy required in depositing material layer by layer, the complexity of the object being printed, and the need for additional support structures in complex designs, all contributing to the overall printing time.