There’s no denying that a clean nozzle is crucial for achieving top-notch 3D prints, but clogs can be a common nuisance for 3D printer users. In this comprehensive guide, we research into the causes behind 3D printer nozzle clogs and provide step-by-step instructions on identifying, cleaning, and preventing clogs to ensure optimal 3D printing results. From recognizing the signs of a clogged nozzle to utilizing effective cleaning methods like cold pulls and acetone solvents, this article covers everything you need to know to keep your 3D printer running smoothly.

Key Takeaways

- Clean Nozzle is Vital: A clean nozzle is crucial for achieving high-quality 3D prints, and identifying a clogged nozzle is critical to maintaining printing quality.

- Causes of Clogs: Common causes of 3D printer nozzle clogs include dirty filament, incorrect printing temperatures, nozzle height settings, and material transitions without proper cleaning.

- Prevention and Cleaning Techniques: Preventing clogs involves maintaining a clean printing environment, using quality filament, and proper cleaning and maintenance practices. Cleaning techniques for clogged nozzles include cold pulling, using cleaning filament, needle cleaning, and acetone solvent baths.

Understanding the Causes of 3D Printer Nozzle Clogs

Importance of Nozzle Maintenance

There’s no denying that a clean nozzle is necessary for achieving high-quality 3D prints. Understanding the causes behind 3D printer nozzle clogs and how to ensure a clean nozzle is crucial for optimal printing results.

Common Signs of a Clogged Nozzle

With material stringing, missing layers, clicking sounds, and inconsistent extrusion patterns being common symptoms, recognizing a clogged nozzle is imperative. If filament is not extruding at all, it may indicate a fully clogged nozzle.

clogged nozzles can lead to a range of issues, such as under-extrusion and poor print quality. Therefore, being able to identify the signs of a clogged nozzle is key to maintaining smooth and successful 3D printing operations.

How to identify a clogged nozzle

Visual inspection

Clearly, inspecting the nozzle for any signs of clogging is the first step. Look for material stringing, missing layers, or inconsistent extrusion patterns. You may also hear clicking sounds in the extruder gears.

Printing tests

An effective way to determine if your nozzle is clogged is to conduct printing tests. If no filament is coming through the nozzle onto the build platform, it could be fully clogged. On the other hand, if the filament extrudes but appears thin or curls up, there may be an obstruction inside the nozzle.

Plus, to confirm a suspected clog, manually feed filament through the hot nozzle while the extruder gear is disabled. If you encounter resistance or observe the filament extruding thinner than usual, a clog is likely the issue.

What causes a clogged nozzle?

Dry filament

Your 3D printer nozzle can get clogged due to dry filament particles that enter the nozzle as the filament is fed through. This can lead to the particles burning and causing blockages.

Moisture absorption

For moisture absorption, filament can absorb moisture from the environment, especially if it is not stored properly. This moisture can cause blockages in the nozzle as the filament passes through.

To prevent moisture absorption, make sure to store your filament in airtight containers with desiccants to keep them dry.

Incorrect temperature settings

| Temperature | Effect on Nozzle |

| Setting the nozzle temperature too low | Can lead to incomplete melting of filament causing blockages |

| Setting the nozzle temperature too high | Can cause heat creep, leading to filament blockages |

With incorrect temperature settings, you can experience clogs due to the improper melting of filament within the nozzle. It is imperative to ensure the correct temperature settings for your specific filament.

Poor quality filament

What you feed into your 3D printer can also affect nozzle clogs. Poor quality filaments with inconsistent diameters or foreign particles can lead to blockages in the nozzle. Always use high-quality filaments from reputable brands

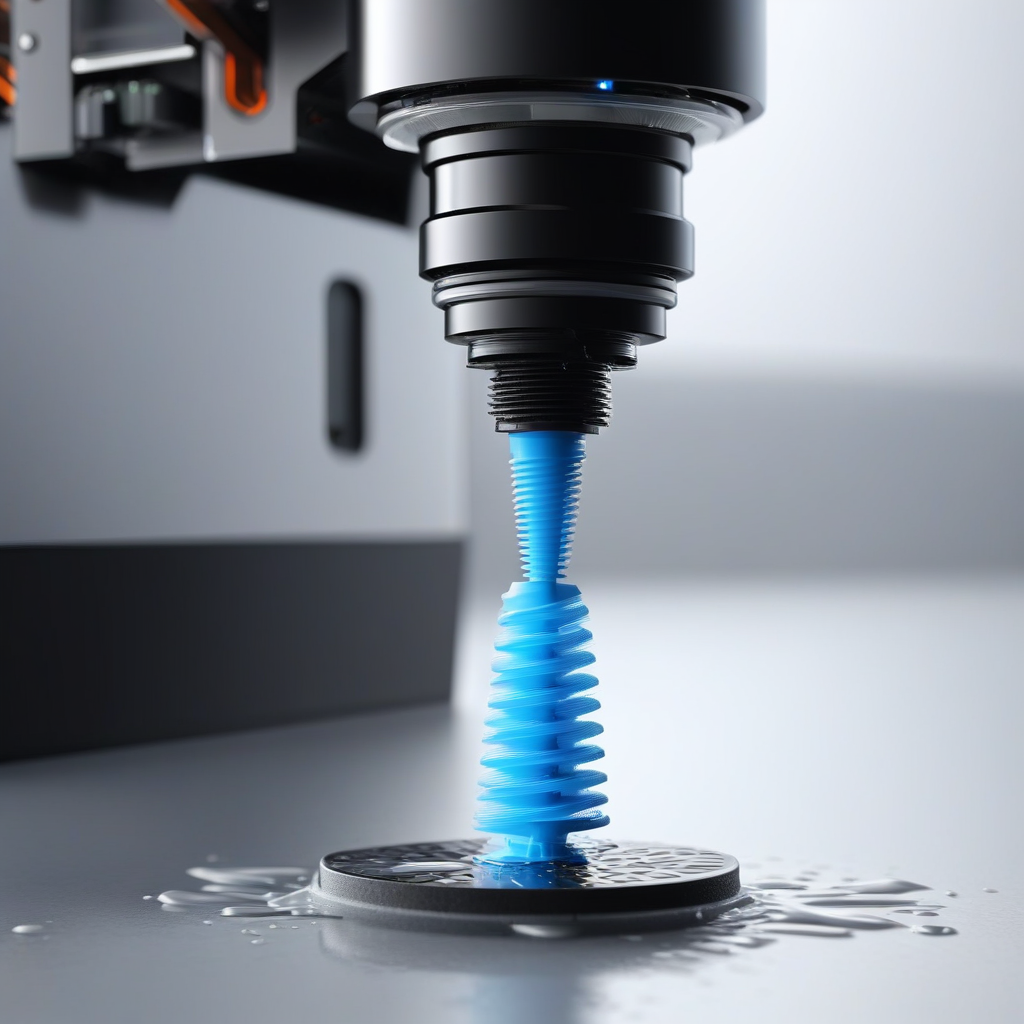

How to clean the 3D printer nozzle

Partial Clog

With a partial clog, using a cleaning filament to clear away debris is effective. Heat the printer to a slightly higher temperature than your last print job and feed the cleaning filament through until it runs clean. A brass wire brush can also help remove residue from the nozzle.

Full Clog

To clean a fully clogged nozzle, methods like using a fine needle to clear debris, cold pull technique, or the atomic pull method can be employed. If these methods do not work, soaking the nozzle in acetone can dissolve the remaining material causing the clog.

The full clog of a 3D printer nozzle can be challenging to deal with, but employing different cleaning methods can help unclog the nozzle effectively. It is crucial to try different techniques and be patient, as it may take a few attempts to fully clear the obstruction and restore proper extrusion flow. If all else fails, replacing the nozzle may be necessary to ensure consistent 3D printing results.

Tips for effective nozzle cleaning

For effective cleaning of your 3D printer nozzle, it is important to establish a regular maintenance schedule, choose the right cleaning tools, and avoid common mistakes that can lead to nozzle clogs.

Regular maintenance schedule

An effective way to prevent nozzle clogs is to establish a regular maintenance schedule for your 3D printer. By incorporating nozzle cleaning into your routine maintenance tasks, you can ensure that your printer continues to produce high-quality prints without interruptions.

Choosing the right cleaning tools

If you are experiencing nozzle clogs frequently, it may be helpful to invest in specialized cleaning tools such as cleaning filament, wire brushes, needles, or solvents like acetone. These tools can help you effectively remove debris from your nozzle and prevent clogs from occurring.

Avoiding common mistakes

Assuming that a clogged nozzle is solely due to filament buildup is a common mistake. It’s important to also consider factors like printing temperature, nozzle height, and filament quality when diagnosing and preventing clogs. Plus, regularly cleaning the nozzle between material changes can help maintain optimal printing conditions.

Factors to consider when cleaning different types of nozzles

- Brass nozzles

- Stainless steel nozzles

- Copper nozzles

| Brass nozzles | Assuming the nozzle is made of brass, it is important to be cautious when cleaning as brass is softer than other metals and can be easily damaged. Use gentle cleaning methods to avoid harming the nozzle. |

| Stainless steel nozzles | If the nozzle is made of stainless steel, it is more durable and can withstand tougher cleaning methods. Stainless steel nozzles are less prone to damage from cleaning tools, making them easier to maintain. |

| Copper nozzles | Assuming the nozzle is made of copper, it is crucial to use cleaning methods that are safe for copper. Copper is a softer metal and can be susceptible to corrosion, so gentle cleaning is recommended to ensure the longevity of the nozzle. |

Stainless steel nozzles

Assuming the nozzle is made of stainless steel, it is more durable and can withstand tougher cleaning methods. Stainless steel nozzles are less prone to damage from cleaning tools, making them easier to maintain. types of filament deposited on the build platform. When choosing a cleaning method, consider the material of the nozzle to avoid damage during the cleaning process.

Copper nozzles

Assuming the nozzle is made of copper, it is crucial to use cleaning methods that are safe for copper. Copper is a softer metal and can be susceptible to corrosion, so gentle cleaning is recommended to ensure the longevity of the nozzle. Copper nozzles may require more delicate handling compared to other nozzle materials due to their unique properties.

How to prevent a clogged nozzle

Proper filament storage

Despite proper filament storage being crucial in preventing clogs, many overlook this step. Keeping filaments in airtight containers with desiccant packets helps avoid dust contamination, ultimately preventing particles from clogging the nozzle.

Regularly cleaning the extruder

While regularly cleaning the extruder may seem like a tedious task, it plays a significant role in preventing clogs. Accumulated debris can lead to blockages, affecting print quality. Regular maintenance ensures smooth operation and prevents nozzle clogs.

Storage of filaments and cleaning the extruder regularly can significantly reduce the chances of clogs. It is imperative to maintain a clean printing environment and ensure that filaments are stored correctly to avoid any contaminants entering the nozzle.

Using a nozzle cleaning brush

Nozzle cleaning brushes are handy tools for maintaining a clean nozzle and preventing clogs. They allow you to remove residue and buildup from the nozzle, ensuring smooth filament flow and high-quality prints.

It is recommended to use a dedicated nozzle cleaning brush regularly to keep the nozzle free from any obstructions. By incorporating this simple tool into your maintenance routine, you can prevent clogs and ensure consistent printing results.

Additional tips for preventing clogs

- Monitor temperature and humidity levels in your 3D printing environment diligently.

- Use a filament dryer to remove excess moisture from your filaments before printing.

- Implement a pre-printing routine to ensure proper cleaning and maintenance of your 3D printer.

Monitoring temperature and humidity

| Temperature | Humidity |

| Keep the printing temperature within the specified range to avoid potential nozzle clogs. | Avoid high humidity levels as moisture can lead to filament quality issues. |

Using a filament dryer

For instance, using a filament dryer can help eliminate moisture from the filaments, reducing the risk of clogs caused by wet filament.

Implementing a pre-printing routine

Preventing clogs can be as simple as incorporating nozzle cleaning and filament checks into your pre-printing routine.

Plus, regularly check and optimize your printing settings to ensure smooth printing processes.

How to troubleshoot common nozzle-related issues

Identifying and addressing underlying causes

Now, troubleshoot common nozzle-related issues by identifying underlying causes such as dirty filament, switching materials without cleaning the nozzle, incorrect printing temperatures, and incorrect nozzle height. Address these issues promptly to prevent clogs and maintain optimal 3D printing performance.

Adjusting printing settings

There’s a need to adjust printing settings to avoid common nozzle-related issues. Ensure that your printing temperature is accurate for the filament type being used, maintain proper bed leveling, and adjust nozzle height to prevent filament buildup. These adjustments can significantly reduce the risk of clogs and improve print quality.

Replacing worn-out nozzles

Common issues related to worn-out nozzles can lead to clogs and poor print quality. With regular use, brass nozzles can wear out and become less effective. Consider replacing your 3D printer nozzle every three to six months to maintain optimal printing performance and prevent nozzle-related problems.

Best practices for nozzle maintenance

Creating a maintenance schedule

On average, it is recommended to clean your 3D printer nozzle every three to six months, especially if using brass nozzles. Creating a maintenance schedule can help you stay on top of this crucial task and prevent clogs that could impact your prints.

Documenting cleaning and maintenance activities

Some users find it helpful to keep a log of their cleaning and maintenance activities for their 3D printer nozzles. This can help you track when the last cleaning was done, what methods were used, and if any issues were encountered. Having a documented history of maintenance can be useful in identifying patterns or trends that may impact the performance of your printer.

Scheduling regular maintenance and cleaning is vital for optimal printer performance. It is recommended to follow the manufacturer’s guidelines for specific maintenance tasks and schedules to ensure the longevity of your 3D printer nozzle and overall printer health.

How to Extend the Life of Your 3D Printer Nozzle

Avoiding Abrasive Materials

To extend the life of your 3D printer nozzle, it’s crucial to avoid using abrasive materials that can cause accelerated wear and tear. Materials like carbon fiber or metal-filled filaments can be too harsh on the nozzle, leading to quicker deterioration. To ensure the longevity of your nozzle, opt for smoother, less abrasive filaments in your 3D printing projects.

Reducing Wear and Tear

With regular maintenance and care, you can reduce the wear and tear on your 3D printer nozzle. By cleaning the nozzle regularly, adjusting printing settings correctly, and ensuring proper nozzle height, you can prevent unnecessary stress on the nozzle. Additionally, using high-quality filaments can also contribute to reducing wear and tear on the nozzle.

Concerning reducing wear and tear on your 3D printer nozzle, proper calibration of your printer is vital. This includes ensuring the correct bed leveling, nozzle distance, and filament feeding settings. By maintaining these settings and performing routine checks, you can minimize the strain on your nozzle and prolong its lifespan.

Using Protective Coatings

To add an extra layer of protection to your 3D printer nozzle, consider using protective coatings. Coatings like PTFE or Teflon can help reduce friction and prevent filament buildup on the nozzle, ultimately extending its life. Applying these coatings periodically can ensure that your nozzle stays in optimal condition for longer periods of time.

Using protective coatings on your nozzle can provide an added barrier against wear and tear, as well as help in preventing clogs. These coatings create a smooth surface that reduces friction and promotes smoother filament flow during printing. Regularly applying protective coatings can be a simple yet effective way to maintain the health of your 3D printer nozzle.

Common mistakes to avoid when cleaning and maintaining nozzles

Using excessive force

All 3D printer nozzles are delicate components, and using excessive force when trying to clean them can lead to damage. Avoid using tools that are too large or applying too much pressure when cleaning the nozzle to prevent any potential harm.

Ignoring warning signs

Ignoring the signs of a clogged nozzle, such as material stringing or inconsistent extrusion patterns, can lead to more serious issues down the line. It is important to address any potential nozzle clogs promptly to prevent further complications.

The longer a clog is left untreated, the harder it can be to remove, potentially causing damage to the 3D printer nozzle and impacting the quality of your prints.

Neglecting regular maintenance

Cleaning the 3D printer nozzle regularly is imperative for preventing clogs and maintaining optimal printing quality. Neglecting regular maintenance can result in a buildup of debris and eventually lead to more severe clogs.

For instance, failing to clean the nozzle in between material transitions can result in residue buildup that can contribute to clogs over time. Establishing a routine maintenance schedule can help prevent these issues and prolong the life of your 3D printer nozzle.

Advanced Techniques for Nozzle Cleaning and Maintenance

Keep your 3D printer nozzles in top condition by utilizing advanced cleaning methods. Here are some techniques to consider:

Ultrasonic Cleaning Any By using an ultrasonic cleaner, you can effectively remove stubborn debris from your 3D printer nozzle. The device generates high-frequency sound waves that create tiny bubbles to dislodge dirt and particles. Simply immerse the nozzle in a cleaning solution, place it in the ultrasonic cleaner, and let the machine do the work.

Chemical Cleaning Advanced To tackle more severe clogs, chemical cleaning can be highly effective. This method involves soaking the nozzle in a specialized cleaning solution to break down hardened filament and residue. Always follow safety precautions and manufacturer guidelines when using chemicals for nozzle cleaning.

Electrochemical Cleaning The For advanced users, electrochemical cleaning offers a powerful method to dissolve and remove tough clogs. This technique utilizes an electric current to break down contaminants within the nozzle, providing a thorough cleaning. Ensure proper safety measures and knowledge before attempting this method to avoid any damage to your equipment.

Final Words

Conclusively, keeping your 3D printer nozzle clean is important for achieving high-quality prints. By understanding the causes of clogs and implementing proper cleaning methods, such as using cleaning filament, wire brushes, needles, or solvents, you can effectively clear any blockages. Additionally, preventive measures like maintaining a clean printing environment, using quality filaments, and adjusting printing temperatures can help avoid future clogs. Remember to replace your nozzle periodically and adopt good habits to ensure smooth and successful 3D printing experiences.

FAQ

Q: What are the signs of a clogged 3D printer nozzle?

A: Signs of a clogged 3D printer nozzle include material stringing, missing layers, clicking sounds in extruder gears, and inconsistent extrusion patterns. If no filament is extruding, it could indicate a fully clogged nozzle.

Q: What are the common causes of a clogged 3D printer nozzle?

A: Common causes of a clogged 3D printer nozzle include dirty filament contaminated with dust or dirt, not cleaning the nozzle between material transitions, incorrect printing temperatures, and improper nozzle height settings.

Q: How can I clean a clogged 3D printer nozzle?

A: To clean a clogged 3D printer nozzle, you can use methods such as cleaning filament for partial clogs, a wire brush to remove surface residue, a fine needle or cold pull method for full clogs, or acetone solvent for more stubborn clogs. Replacing the nozzle may also be necessary if cleaning methods fail.